Best Fit Precision owns our casting tooling workshop in Ningbo city, we are able to provide different tooling option for our customer:

- Cast iron tooling

We are able to offer cast iron tooling for low volume die casting parts for our customer, which means the tooling are made by cast iron and the tooling life cycle is around 5000 shots and this provide a very low cost option so that the customer doesn’t have to invest high cost standard for new product development.

- Precision steel tooling

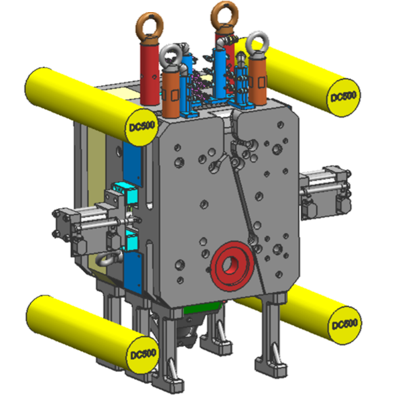

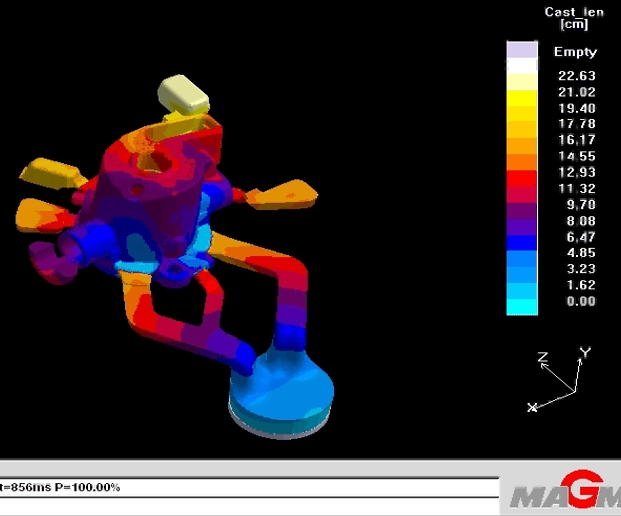

We design and make die cast tooling for various Aluminum, Zinc and Magnesium casting processes that ensure near net shape castings with dimensional accuracy, close tolerances, and smooth surfaces that eliminate or minimize post casting machining.

We’re experts in prototype, production-intent development, and production tooling. While your different castings require different aluminum alloys, all your projects require quality and excellence. Our innovative tooling solutions ensure quality castings for foundries and advanced manufacturers of aluminum castings with complex geometry and high performance demands.

Lots of advanced manufacturers worldwide benefit and trust Best Fit Precision for their aluminum casting tooling solutions.

Cast Tooling that we involved in:

- Automobile & motorcycle machinery parts

- Transmission parts (Gearbox Housing, Piston, Valve Plate etc)

- Cooling system parts (Water Pump, Fan Clutch, Oil Pump etc)

- New Energy Vehicle Parts(Drive Motor Housing, Motor Cover, Controller Shell & Housing etc)

- Electrical Engine and Generator components

- Motor housing

- End cover

- LED lighting lampshade shell